HMS Unicorn is the 'missing link' in most attempts to evaluate Britain's armoured carrier doctrine in World War II. She was the embodiment of the understanding of their limitations - and an acknowledgement that extended operations was a core fleet carrier role.

“Repair and even the major maintenance work could not be carried out in the hangars of an operational carrier without interfering with flying and hence it was decided to build a maintenance ship.”

OVERVIEW

The reduced operational endurance of the armoured carriers was a known compromise of their treaty-bound design. But it was thought the Empire’s vast network of naval bases around the world would provide more than ample facilities and support.

But the same Abyssinian crisis of 1935-36 which inspired their design also proved the need for sustained operations. The crisis demonstrated fleets - including carriers -needed to be deployed quickly from one theatre to another, with little time available for their land-based support infrastructure to follow them. There was also the risk such land facilities would fall to the enemy.

A committee set up in 1936 to assess just this kind of challenge determined the need for 'afloat support' facilities. This would be an assembly of repair, maintenance and depot ships that could follow the fleet. They were to be moored in anchorages near the seat of action, but were not expected fight with the fleet itself.

Another key lesson learned through the FAA's forward deployment during this crisis was that a month’s worth of intensive flying could result in an attrition rate of 20 per cent of aircraft lost and a further 10 per cent needing significant repair. If key bases fell or were rendered unusable by constant enemy attention, fleet carriers could rapidly be depleted of their primary weapon.

So, in 1937 (two years before the committee handed down its report), the need for a mobile aircraft depot ship – a maintenance carrier - was quickly agreed upon, even as the plans for the armoured carriers themselves were being drawn up. The design process for this support carrier, however, would be drawn out and difficult.

Such a ship would be particularly useful because of the anticipated cramped conditions aboard the newly proposed armoured fleet carriers: Their hangars would be enclosed – reducing the available width for stowage and maintenance.

They were also expected to carry only 33 aircraft. To keep them effective, extensive and readily available support and resupply would be needed.

As support vessel, the 14,750 ton (20,300 full load) design was given the useful – but not combat suited - speed of 24kts. The mobile workshop would also carry its own defence.

The original intention was for one ship to service three fleet carriers. With an intended six armoured carriers, as well as the Ark Royal, Courageous and Glorious, this meant a production run of three vessels.

Controller Admiral Sir Reginald Henderson – the same man behind the fast-tracked armoured carrier design – would insist this aircraft depot have most of the features of an operational aircraft carrier. His experience off Ethiopia had taught him having a spare deck in times of crisis would be invaluable.

Therefore she was given arresting wires, a catapult, munitions stores – andan armoured flight deck.

“Each of the naval limitation treaties called for full and accurate disclosure to the other signatories of the main characteristics of new ships. It is probably true that all the countries bent the rules and most broke them. The RN’s only serious breach was the design of the Unicorn, declared as a depot ship but completed as a fully-fledged carrier with a heavy armament and an armoured hangar. This was almost accidental as the significance of a series of changes was not appreciated.”

Unicorn, as completed, was in many respects indistinguishable from an active fleet carrier.

This presented a problem.

The UK had already filled its treaty quota of combat-capable carriers.

After a degree of hand-wringing and reading between treaty lines, the Naval Law Department recommended Unicorn still be classified as an auxiliary. After all, that was the intention of her design – to support carriers in much the same way armed tenders supported submarine and destroyer flotillas.

The fact she looked like an aircraft carrier was a necessary consequence of her capabilities. And didn't destroyer tenders - with their destroyer like lines and armament - look like stretched destroyers?

But the RN decided not to press its luck: It ordered only one ship, not the three that were believed necessary to support the number of active fleet carriers. By 1939 the issue was moot anyway: All available ship production resources had already been allocated for emergency war program builds. There was no room for more aircraft auxiliaries.

Laid down in June 1939 and completed in November 1941, the same delays and shifts in priorities that afflicted Implacable and Indefatigable were to hobble Unicorn.

She would not be completed until March 1943

Such was the flexibility of her concept and design that she essentially became the precursor to the flight-deck equipped SVTOL/Helicopter/Landing Craft assault ships so common in today's navies.

Once the international treaties were torn up with the outbreak of war, HMS Unicorn would find herself actively deployed as a combat carrier from time to time.

In fact, it was the first thing she did: She was loaded up with Seafires and Swordfish and sent on an escort/ferry mission to Gibraltar and then took part in decoy operation (Operation Governor) in July 1943, off the coast of Norway.

But her most significant action would be at Salerno. Here she proved that she really was more suited to her intended auxiliary role. The main problem was a lack of accommodation for active pilots, but her flight deck also was not as refined as that of a fleet carrier and could generate challenging vortices for landing aircraft

Later, as the Fleet Train was being assembled for the Pacific, the original requirement for three maintenance ships made itself painfully apparent.

An urgent decision was taken to convert two of the new Colossus class Light Fleet Carriers as maintenance carriers. While such an emergency adaptation of this design in its late stages of completion allowed major maintenance, fuselage repair and testing work, these ships did not have the engine workshops or defensive armament of the Unicorn. Nor did these hasty conversions have any aircraft operating equipment such as arrestor wires and catapults. Aircraft would be hoisted aboard.

HMS Pioneer was completed in time to reach the Pacific for two months’ worth of operations before the war ended. Perseus, however, was too late.

HMS Unicorn in February 1945, carrying spare Hellcat fighters on her flight deck from Ceylon to Australia. Note how the old SEAC roundels have been roughly painted over. In the hangar, as seen through the lift left open for ventilation, can be seen aircraft repainted with the new BPF roundel.

FLIGHT DECK

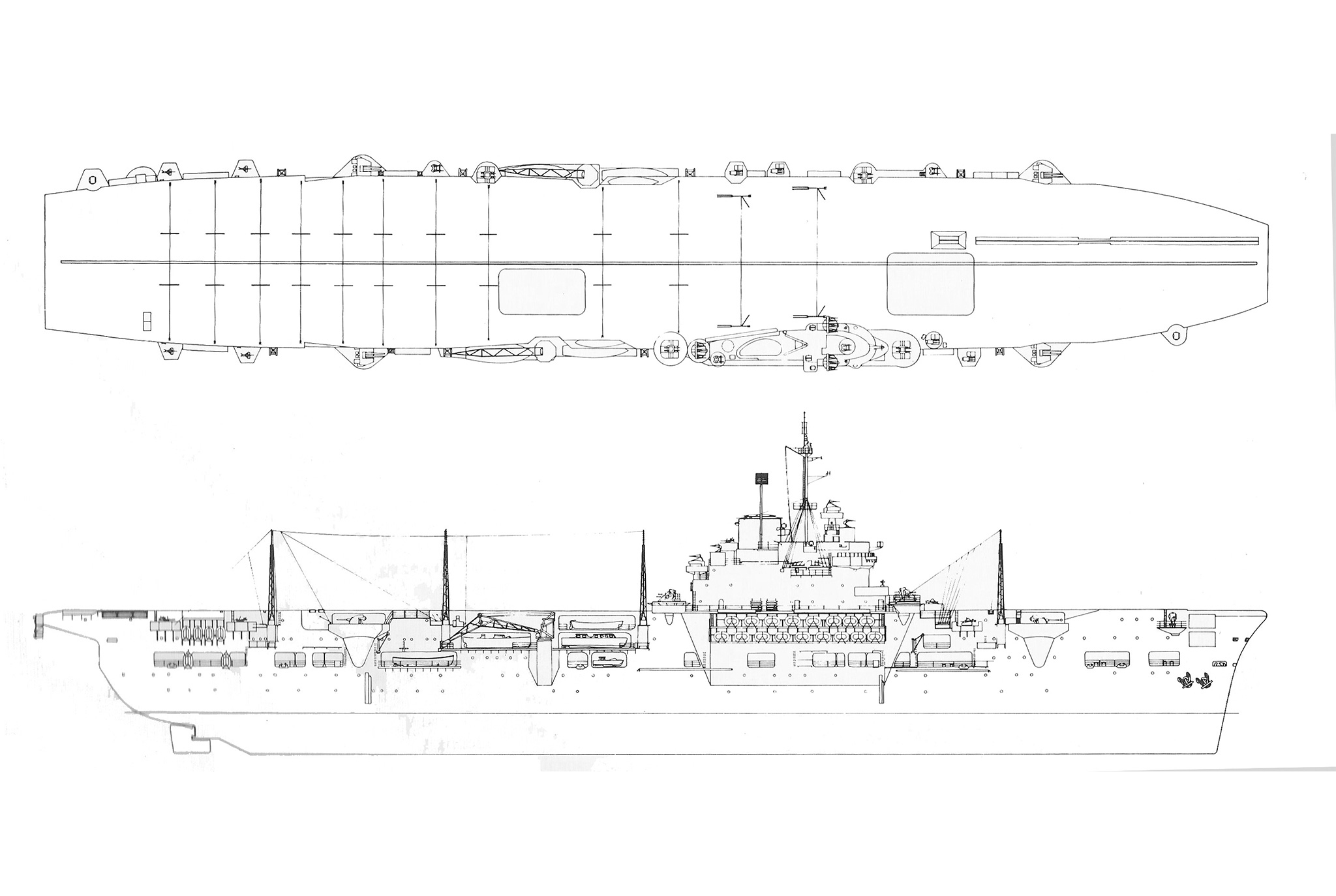

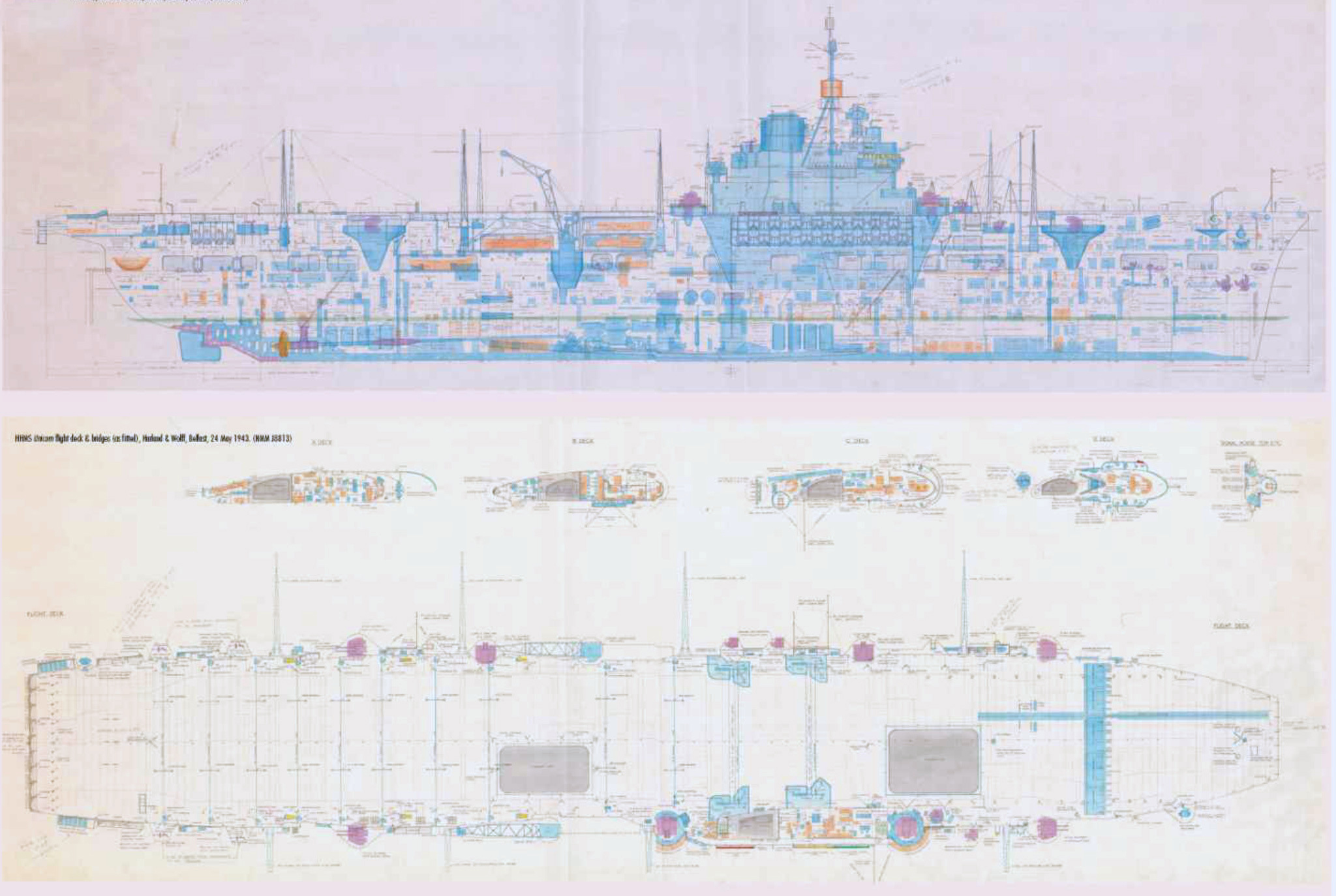

Unicorn had a somewhat stunted appearance, resulting from the great height of her two 16ft 6in hangars and shortened 640ft length.

The 90ft wide flight deck was much more uniform than the armoured carriers she was to service: There were no intruding recessed Pom-Pom or 4.5in turret sponsons.

Her bow lines were also more reminiscent of the Ark Royal, with its edges sloping inwards a little over a prominently plated prow.

But this did not equate to an easier deck to land on. As Unicorn was designated an auxiliary, nowhere near as much care was taken in her aerodynamics.

The airflow from the bow and around the island was, as a consequence, to have a noticeable impact on aircraft making their landing approach. Pilots would report an experience like "falling off a cliff" as their aircraft crossed over Unicorn's stern, a sudden drop out of the sky which could cause harder than expected landings.

It is interesting to note that Unicorn’s ship’s bridge was the highest in the RN, sitting 95ft above the wavetops.

LIFTS

Unicorn had two lifts, a broad 46ft by 33ft platform positioned just forward of the island and a narrower 46ft by 24 lift amidships. They were designed to hoist loads of up to 20,000lbs with a cycle time of 46 seconds.

The forward lift was intended to be able to shift non-folding aircraft into the hangars.

Both were offset slightly to starboard, giving her flight deck a somewhat unbalanced appearance.

“The gear fitted in Unicorn could accept 20,000lb but it was so strong that, initially, it would pull a Seafire in two! ”

ARRESTING GEAR

As per Controller Henderson’s wishes, a full set of six arresting wires were fitted aft. These could trap 20,000lbs at 60knots.

Most written accounts state Unicorn operated only one crash barrier. But engineer's drawings of the ship appear to show two set into the deck at the level of the island.

Either way, the crash barrier was designed to accept a similar load as the arrestor wires, but with a much shorter ‘pull-out’.

ACCELERATOR

The BHIII hydraulic accelerator was the same as fitted to the armoured carriers. It was capable of propelling 14,000lbs at 66 knots when using the tail-down launch method.

It would most often be used to launch aircraft while stationary in harbour for return to their home carriers.

Inside UNICORN's hangar. Here she has three Corsair's tightly stowed, with two Firefly fighter-bombers in various states of assembly in the background.

HANGARS

Hangar space was to be sufficient to contain 48 aircraft with their wings folded, with a further eight having their wings spread as part of their maintenance program.

This was achieved through a double hangar design and 16ft 6in hangar heights. Combined with the openings to the hangars from the stern, this enabled Unicorn to even service floatplanes. But the need for extensive workshop space restricted hangar lengths. The upper hangar was 324ft by 65ft, and the lower 360ft by 62ft.

Nevertheless, as completed, Unicorn had a total hangar area of some 40,000sq ft - almost the same amount as HMS Idomitable.

The intention was for reserve aircraft to be stuck-down into the lower hangar, while the upper hangar would be where maintenance and repair work would be conducted.

Like the fleet carriers, Unicorn's hangars could be divided into sections with fireproof curtains.

In a ferrying capacity, Unicorn could carry 50 to 80 aircraft (depending on size). As an operational combat carrier, her facilities could support 35 machines. She could operate 20 non-folding Seafire IICs, or ferry 69 of the folding Seafire IIIs.

As a maintenance carrier, she could have about 24 aircraft under repair at any one time.

MAINTENANCE FACILITIES

Unicorn’s hangars were intended to be wide enough and high enough to allow all foreseeable aircraft designs to have their wings spread and refolded.

Above them, on both hangar decks, was an extensive network of rails and hoists. These would allow heavy items – such as engines – to be hauled out of the aircraft, transferred to the appropriate workshop, and returned once again when repairs were completed.

A large engine repair shop and a test compartment was positioned near the bows under the flight deck with two large, rectangular openings. Here engines could be mounted to run at full power, with enough airflow to allow noxious fumes to vent.

Individual workshops were incorporated into the design - each equipped and supplied for roles such as airframe, radio, electrical, woodwork and fabric repairs. Storage space carried a comprehensive range of spare parts.

During the design phase it was estimated an average repair job would need six days for completion, with three work teams of six men each working in rotating shifts.

Unicorn’s stern was particularly unusual: It was squared off and open to allow engines to be run while inside the hangars.

The aft flighdeck overhung this space considerably and had hoists which could lower a motorised lighter to the level of the upper hangar to be loaded with aircraft, and then settled into the water for transfer.

This lighter was a central piece in Unicorn’s ability to be fully self-supporting.

Aircraft artificers and mechanics were formed into two Special Repair Parties, each supplied with British and United States toolkits.

In 1944 Unicorn’s hangars and workshops would undergo a degree of modification and reorganisation to allow two streamlined ‘production lines’ - with one workshop specialising in either English or US powerplants.

As a result of this reorganisation, Unicorn was fully capable of servicing and maintaining all six types active with the British Pacific Fleet – Seafires, Fireflies and Barracudas, as well as Corsairs, Hellcats and Avengers.

Hugh Langrishe, in Malcolm Smith's Voices in Flight: The Fleet Air Arm: Recollections from Formation to Cold War

The initial impression of American aircraft was their superior external finish. They seemed to have an air of robustness, which the British ones lacked. This was most noticeable in the design of undercarriages, which would take almost unlimited side loadings, as well as in the vertical plane. The rearward retraction system on the Hellcat and Corsair was much stronger than the British systems of the period. In spite of its excellent wide track, the Firefly I was involved in a number of landing accidents due to a lack of strength at undercarriage attachment points. Later Corsairs were fitted with an admirable ‘non-bounce’ oleo, which could absorb the shock of a considerable vertical drop without sending the aircraft back into the air, a great advantage when landing-on in heavy seas. American treaded tyres fitted to all their types stood up to the job well and sorties flown per tyre change were nearly double those for British aircraft with smooth covers. The Seafire, which was the most expensive of the latter, frequently wore out a cover in fewer than ten landings.

American hydraulic systems generally operated at a much lower pressures than those in British aircraft. This necessitated comparatively bulky components, a disadvantage partly offset by greater robustness in service. If the aircraft were received in a reasonably new state there was little trouble but machines ‘new’ only from lengthy storage could be a nightmare. By about 120 flying hours, fluid weeping became apparent from numerous components.

It was very easy to destroy the batteries of Avenger aircraft if start-up procedures were not properly observed and a trolley accumulator was not available. The Jack & Heintz electric inertia starter consumed a large amount of power and this could generate sufficient heat in the battery to melt the top and boil the electrolyte.

American electrical components only seemed to have a small safety factor. Generators broke down under conditions only fractionally exceeding normal load. The aim seemed to be to produce an article lighter, power for power, than British counterparts. The American product certainly looked good; glossy enamel and a highly-polished finish were the norm. British components were nothing much to look at but efficiency was much higher.

American build standards, metalwork, skinning and riveting etc were particularly good. However, replacement assemblies, such as engine cowlings, ailerons, tail planes and elevators, often would not fit. It seemed as though jig limits and manufacturing tolerances were excessively wide and, combined with selective assembly, produced components that were all of noticeably different sizes...

Machine-shop facilities in action aboard HMS UNICORN.

All three American front-line types were fitted with large two-row radial engines, the fighter aircraft with the Pratt & Whitney Wasp R-2800 and the Avenger with the Wright Cyclone R-2600. Hamilton Hydromatic three-bladed metal propellers of varying sub-series were standard fittings. Early models of the Corsair were fitted with the R-2800-8 sub-series of motor, incorporating Stromberg carburettors. Later aircraft used the R-2800-8W, which incorporated a water-injection system. Early Hellcats were powered by the R-2800-10 and the later F6F-5 Hellcat II by the R-2800-10W, also incorporating water injection.

Marks I and II Avengers were powered by the Double Cyclone R-2600-8 with Holley carburettor. The TBM-3 had a series -20 engine which, with Bendix-Stromberg carburetion, gave it an extra 150 hp. Engine suspension in all these aircraft was on ‘dynafocal’ flexible mountings, which considerably reduced vibration in the airframe and increased the comfort of the crew. In contrast British aero-engines were mounted on hard rubber blocks. It was said that it was so quiet and smooth in a Corsair cockpit that the pilot had to reassure himself from time to time by a glance at the instruments that the engine was actually working.

Although powerful these engines were not highly reliable. In most cases faults were not so much the consequence of poor design as of low-grade materials and a poor standard of ancillary equipment. In the Avenger, after around 100 engine running hours, loss of power, poor starting and rough running were sometimes experienced, caused by undue oiling of the sparking plugs in the lower cylinders. This was traced to considerable wear in piston rings and cylinder bores, leading to engine rejection for overhaul after a very short life..

Most early Corsairs and Hellcat were fitted with Eclipse cartridge starters. The pistons in these would frequently seize after as few as thirty cartridges had been fired, due to heavy deposits of carbon. This trouble was overcome when Jack & Heintz electric starters were substituted in later Corsair IVs and Hellcat IIs.

The troubles experienced with Holley and Stromberg carburettors usually led to assembly changes, although it is probably fair to say that, had engine fitters received proper training on these instruments, rectification might have been possible in situ more often. There was, in any case, a chronic shortage of new or overhauled carburettors.

An engine defect in some Avengers may have caused crashes for which no explanation was ever found, particularly if the aircraft went down into the sea. After take-off at maximum power, increasingly heavy clouds of oily smoke issued from the exhausts and the engine cut. Examination showed that the housing of the blower impeller rear bearing had failed at its weakest point, the mixture duct entry to the impellor. Oil was released from behind the bearing at engine pressure and was at once drawn into the engine, fouling the plugs.

All the American powerplant installations suffered from failures of exhaust stack assemblies. In all cases the exhaust systems were threaded between the cylinders to the rear, necessitating long, curved lengths of piping. The Avengers had a collector trunk at the rear of the engine, leading to a large-bore outlet low on each side. Fighters had multiple ejectors. The cooling of the pipework was quite inadequate, most of it being blanketed by the cylinders, and cracks were prone to develop at bends and welded elbows, and at collector-ring junctions in the Avenger. The Bristol engine system of a leading edge collector ring with short and almost straight branch pipes from the front of the cylinder heads would have been preferable.

MEDICAL FACILITIES

A little known function of HMS Unicorn was to act as a floating hospital. She had a large sick bay and a fully equipped surgery. There were also dental rooms. This was in addition to the ship’s own twin medical stations intended to cope with those injured when the ship was damaged herself or any 'overflow' from the hospital facility.

PROTECTION

Unicorn was not intended to operate under combat conditions. But she was expected to be close. Very close.

So she was given a level of protection intended to resist moderate damage.

Chief among these features was her armoured flight deck of 2in NC plate. Limited to a length of 378ft, the protection extended the full width of the ship. This desk was intended to offer protection against 250lbs bombs.

Unlike the fleet carriers, Unicorn had an extra level of strengthening on her lifts. These had 1in Nickel-Cement (NC) grade armour plates on their platforms.

Unicorn, however, did not have an armoured ‘box’ hangar.

Instead, there were 2in armoured crowns and 4 to 4.5in sides around her magazines.

There was no belt armour, but her machinery spaces had 1.4in armoured internal bulkheads to protect the spaces against torpedo explosions, mines and near-misses.

Torpedo protection, as designed was against a 440lbs warhead.

ARMAMENT

As with most of Britain’s depot ships, HMS Unicorn was expected to contribute to her own defence. To this end she was completed with four twin 4in mountings, one mount covering each “quarter” of the ship. Some 3816 rounds of 4in ammunition were stowed.

The dual-purpose guns were supported by four quadrouple 2pdr Pom-Poms – one at each end of the island, and two two on the port side amidships. Standard Pom Pom ammunition loads was 1200 rounds per barrel.

Extra Pom-Pom mounts, 40mm single Bofors and 20mm Oerlikon guns were fitted as the war progressed.

During the Korean war Unicorn employed her 4in guns in shore bombardment duties. She was probably the only carrier to have been used as gunfire support!

RADAR

Unusually, HMS Unicorn was the first ship to be fitted with the Type 281B air warning and fighter control radar. This gave her a valuable role in the harbour and at-sea defence of the fleet.

There were also fire-control radars fitted for her 4in gun directors and Unicorn also had a Type 72 homing beacon as part of her aircraft operating suite.

MACHINERY

Unicorn had a two-shaft installation along similar lines to that fitted in contemporary destroyers: Two boiler rooms of two boilers each, and two engine rooms.

The reasoning was simple: This freed up extra space for storage and workshops.

Nevertheless, Unicorn’s machinery could generate 40,000ships and propel her at up to 24 knots, though her usual sea speed was 22 knots.

While not an ideal speed for an aircraft carrier, it was – once again – fairly standard for one of the RN’s depot ships.

At 20kts, Unicorn could steam some 7500 miles with her 3000 tons of on-board fuel.

In the worst grade of condition - tropical waters, six months out of dock - Unicorn was estimated to have an endurance of 7000 miles at 13.5kts.